Product name: Safflower Seed oil powder

Synonyms: Safflower seed oil powder; Saff Flower oil powder

Plant source: Seeds of Carthamus tinctorius L.

Material source: Organic Safflower oil

Active Ingredient: Linoleic acid(Ω-6)

CAS Number: 60-33-3

Molecular formula: C18H32O2

Molecular weight: 280.45

Characteristics: Off-white or slight yellow-white free flowing powder, CWS(cold water soluble).

Safflower Oil Powder (Omega-6)

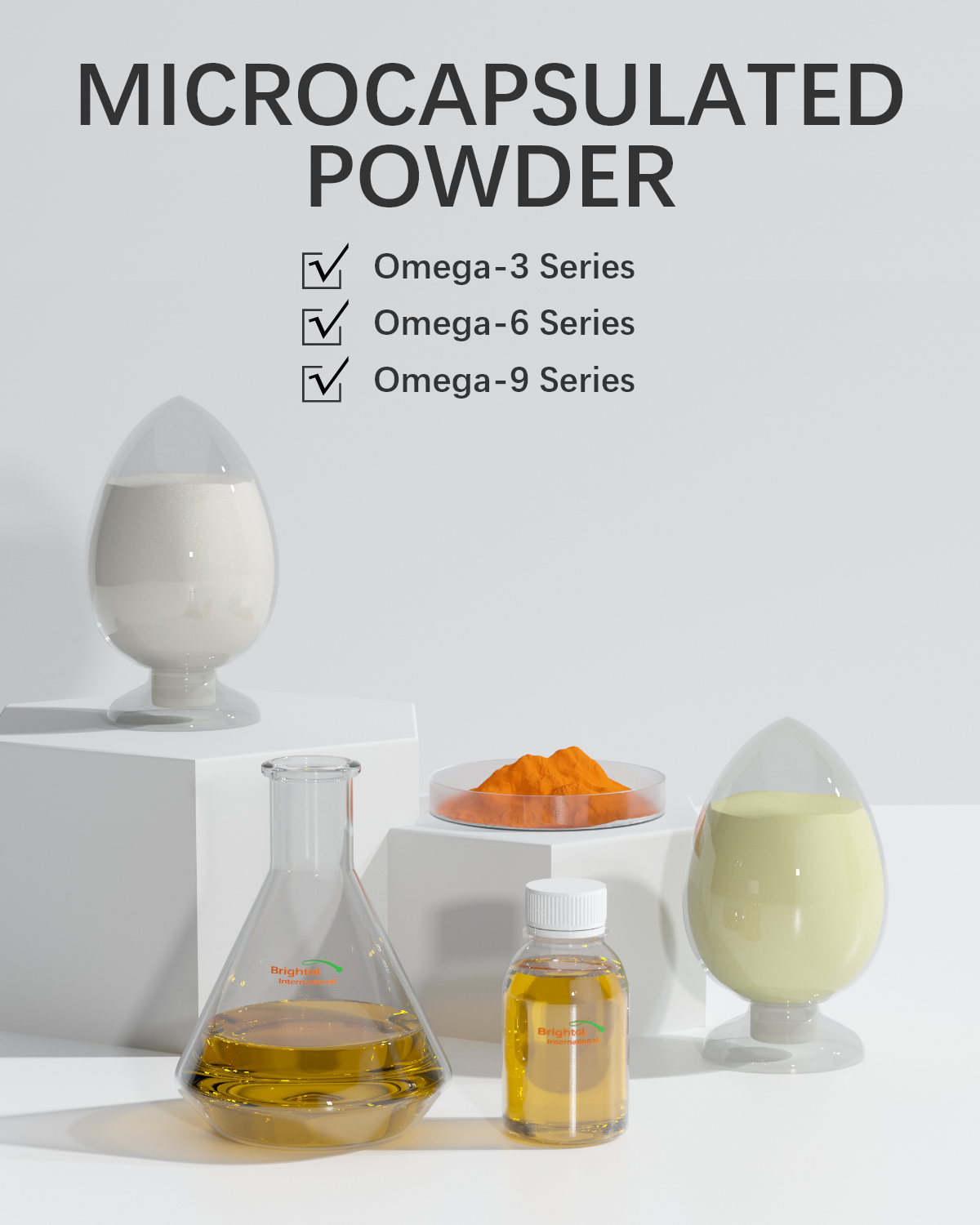

Microencapsulated Safflower oil powder contain linoleic acid (omega-6),oleic acid and palmitic acid, it also contains vitamins E, Oryzanol, Phytosterol and other nutritional ingredient. Microencapsulated Safflower oil powder is a nutritional supplement or nutritional enhancer, widely used in food, health food, dairy products and beverages applications, Microencapsulated Safflower oil powder has the outstanding use advantages than Safflower oil.

Product name: Safflower oil powder

Synonyms: Safflower seed oil powder; Saff Flower oil powder

Plant source: Seeds of Carthamus tinctorius L.

Material source: Organic Safflower oil

Active Ingredient: Linoleic acid(Ω-6)

CAS Number: 60-33-3

Molecular formula: C18H32O2

Molecular weight: 280.45

Characteristics: Off-white or slight yellow-white free flowing powder, CWS(cold water soluble).

Function

1. Boosts immune system

2. Effective remedy against obesity

3. Aids in regulating menstrual cycles

4. Helps to keep hair and scalp healthy

5. Boosts quality and appearance of skin

6. Aids in preventing and managing diabetes

7. Helps to regulate cholesterol levels in body

8. Reduces risk of atherosclerosis and strokes

9. Helps to decrease severity of PMS symptoms

Advantages of Microencapsulated Safflower oil powder VS traditional Safflower oil

1) Protecting an active ingredient during food processing and storage

2) Improved handling of the active ingredient, for example, conversion of liquid in solid

3) Masking off-taste, odor and color

4) Creating textural and flavor effects

5) Control of active ingredient release.

6) More convenient handling during processing

7) Raises the additional values of production, extending the whole supply chain.

8) Increases the complexity of processes and characterization of fortified products.